Our laboratory is at your disposal for the realization of any type of leather product. We will be able to make a difference for your brand and be able to embellish each different collection of leather handcrafted belts with a touch of traditional craftsmanship and a note of original innovation.

At all stages of our production, we guarantee the customer maximum timeliness and meticulous attention to finishes. The wise combination of artisan tradition and technological innovation is the basis of the company policy of the G&G Cinturificio. Two elements to say the least contrasting but which, uniting under our brand, complement each other by tracing our company profile. We have always taken advantage of technological innovation in our favor, investing in the latest generation machinery and offering our customers increasingly original processing techniques.

In each production, however, the most innovative processing techniques are completed with manual finishes and seams performed according to the most ancient artisan traditions. The equipment in our laboratory allows us to satisfy even the expectations of the most demanding customers, creating unique and personalized items and at the same time ensuring traditional manufacturing and skilful manual finishes.

In our company, the tradition of the past marries the innovation of the future and, making progress our goal, allows us to offer exclusive and innovative leather processes. Our warehouse is at the customer's service by offering a wide range of leathers: from leather to pony skin, up to calfskin or the most modern printed, washed and elastic fabrics.

Manual cutting

The cutting takes place with the strip-cutting machine, in which the blades are inserted and the thicknesses can be made of any type of belt heights, the leather is previously headed in order to calculate how many strips can come out, in order not to have waste. Start-up takes place through a pedal that the operator must operate simultaneously in the passage of the skin on the blades.

Automatic cut

The cutting takes place through the latest generation Flash Cut automatic machine, which cuts with blades and perforates any type of material such as leather, leather, plastic, eco-leather. Through the PC you create the file of what you want to cut or that the customer requires of any shape and size, the machine reads the file and reproduces it perfectly identical to the design. In addition to belts of various shapes and sizes, we can also produce key rings, bracelets, small leather accessories, collars and leashes of all kinds.

Bonding of parts for coupled or convex belts

The gluing takes place with the Step machine, it is a modern automatic machine, which through the spray nozzles the glue drops, the machine has a roller that automatically turns a conveyor belt so the strips are coupled together, and also has the oven to dry. It is equipped with 2 cameras so you can see the beginning and end of the conveyed strips so that two people can work at the same time.

Pre-drilling for rivets

The FCA86 / 2 machine is an automatic punching machine, where the leather strip is inserted and punches according to the punches that are inserted with the various holes of various sizes and distances. It can pierce the entire length of the belt.

Riveting

We have many automatic air machines that apply rivets, eyelets and rhinestones of various types and sizes. For each specific need for each belt.

Hot roller on calf or leather

The machine works with a rotating brass roller, previously heated to high temperatures, the belt is inserted and passes under the roller along its entire length. You can use rollers with various designs, so the design takes up all the space of the height of the belt or even with a smooth roller just to give the effect used on the edge. I know it can do better on leather and hides if vegetable tanned because the print is much better impressed.

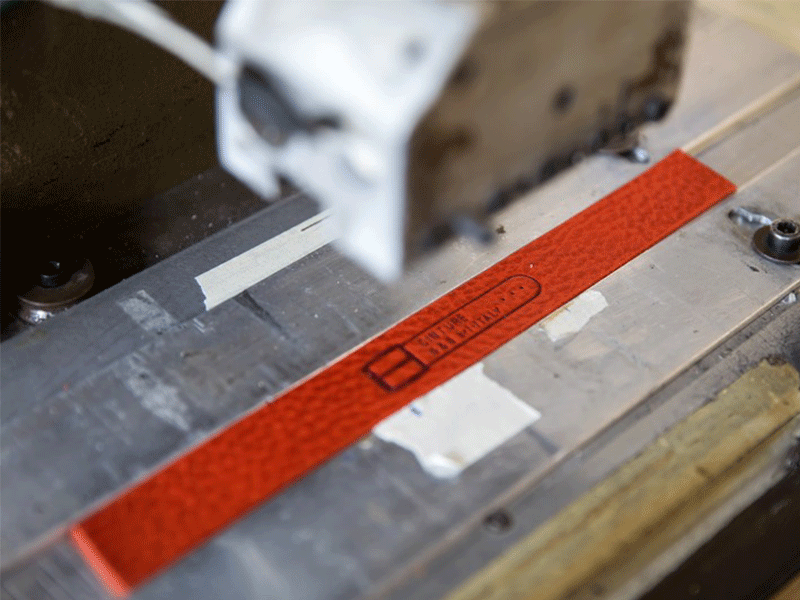

Definition of taglia

The TD90 machine is a machine that simultaneously performs these processes: holes for the belt, slit for the buckle, sometimes the tip and then the length of the belt is set, i.e. it makes the size, also prints on the back hot or with foil the various brand names.

Edges coloring

The edge dyeing machine works on the edges of the belts giving both the base as the first time, and also the other two or three times of color, it slips and gives color to the edges.

Edges brushing

With the brushing machine it is possible to polish the edges of the belts in order to have them beautifully smooth in order to then be able to make the base color and also in the subsequent coloring steps.

Hot stamping on leather or leather

We have several machines that hot stamp logos, small designs, hot foil or small shapes.

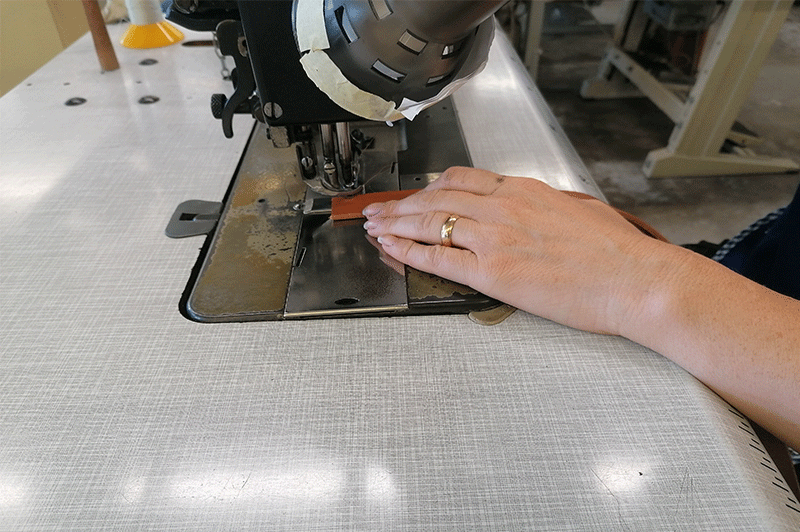

Hand stitched

Our craftsmanship also lies in making seams by hand, both the buckles and the edge of the belt can be sewn.

Machine stitching

Usually the welds to attach the buckles are made with the machine automatically while for sewing the edges we have different linear ones based on the thread count.

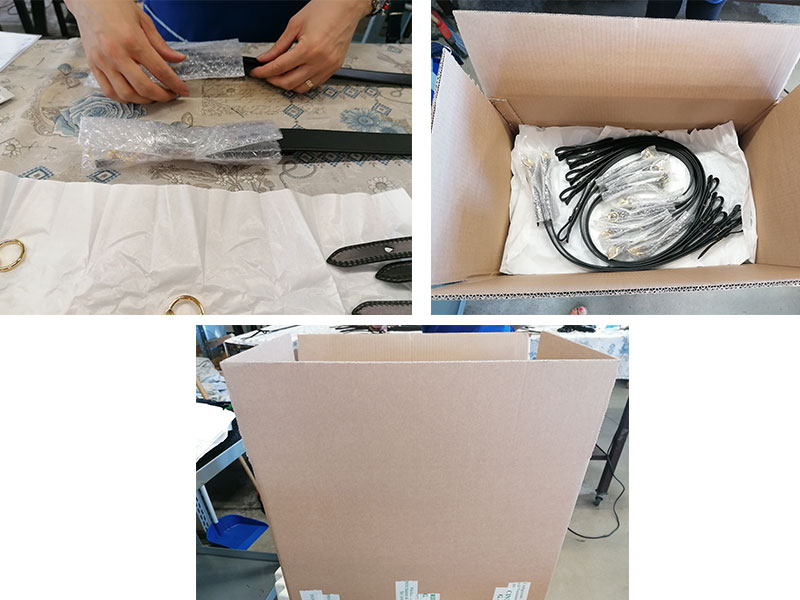

Pack and packaging

We are able to supply a complete packaging with multi-bubble bag for buckle, tag and label with bar code if the customer requests it, all inserted in standard boxes of various sizes. We can also have customized bags according to the customer's needs.

Contact us

For more information on our leather belts and accessories production service, we recommend that you contact our company. Our staff will be happy to provide you with all the explanations you need.